A new vintage lathe in the shop: The Hardinge HLV!

The best finds always pop up in the summer, when everyone else is on holidays! Still, they are not always nearby or easy to deal with. When this 1954 Hardinge HLV precision toolroom lathe appeared on the horizon, it took all of 5 minutes to decide to go for it and one week of frantic international phone calls to organize everything. An engineer was sent to check it over, local transportation to an industrial machinery crating facility, international transportation, more local transportation and another week later it was finally in our yard!

Big and heavy, as good lathes tend to be, the legendary Hardinge HLV is widely considered to be one of the finest and most accurate lathes ever made. They are still highly sought after and incredibly rare. We had been looking for one of those for over five years. With increasing demand for precision parts for vinyl record manufacturing equipment, the HLV is one of the very few lathes ideally suited for the task, offering extreme precision and repeatability along with ample capacity for bigger parts.

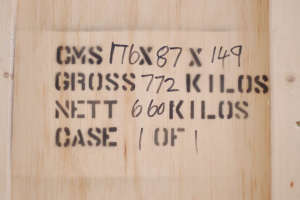

The load-in had to be carefully planned. The easiest way into the workshop is through a porch, surrounded by hand rails, standing a meter above ground and not really designed for 772 kg lathes to sit on...!

We designed and installed a steel scaffolding-type support structure for the porch, to withstand a few extra tons, including impact in case the lathe should decide to do an emergency landing...! The health and safety of the crew (and lathe) is, naturally, of utmost importance.

Not having access to a crane with an adequately long reach and lift capacity, we used a vintage Toyota forklift truck (to be period correct), fitted with custom long-reach forks. Slings were used as described in the HLV manual, protruding handwheels and levers were removed, and soon this heavy chunk of old iron was hovering high above ground and over the handrails!

We were all screaming a little bit inside and holding our breath while this was happening, apart from Vangelis, the forklift truck operator, who remained calm and confident. He maneuvered truck and load with impressive accuracy. Thanks to Vangelis (not related in any way to the famous composer of the same name, although J. I. Agnew's grandfather had indeed conducted the first recordings of Vangelis, Demis Roussos and Lucas Sideras), the lathe landed smoothly on the special platform trolley we had designed and built for it, with which it was wheeled into the workshop.

Although it is in an incredibly good shape for its age, a complete restoration is in order for a lathe of this caliber, to perform to its full potential for many more years to come. J. I. Agnew has considerable experience in the restoration of vintage precision machine tools, so you can expect to be reading more soon about the Harding HLV restoration project.