Direct-Drive Conversion on a Fairchild Lathe

The Fairchild line of disk recording lathes, first appearing in the early 1930’s, featured a General Electric hysteresis synchronous AC motor, running at high speed, with a worm and gear reduction to drive the platter. While this system in its various permutations in their different models was impressively well made and performed well for its time (see here for a more detailed description and pictures), a direct-drive system with a floor mounted motor is clearly the way to go if the highest level of performance is to be attained.

We have had a TT15 in the lab for several years now and tried it on multiple lathes. With some modifications and tweaks, it can work extremely well.

The first step is to make a good adjustable base. Then we need a heavy flywheel to guarantee good rotational stability. Next, we need a way to couple it to the driveshaft. We tried a few different couplers, but it was clear that something special would be needed for ultimate performance.

Having a precision machine shop in-house, the inspiration was there: What do metalworking lathes use to hold and rotate a workpiece?

So we mounted one on a special suspension system, machined it true and fitted it to the motor assembly.

This will accurately grip the shaft and rotate it.

The toothed wheel half-way up the shaft is part of an optical tacho sensor assembly. This senses what the platter is doing and along with several other sensors, forms the multiple feedback loops used to regulate the movements of the lathe.

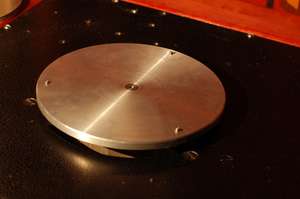

At the top we have a subplatter with a three-point adjustment system to level the platter and eliminate run-out. This needs a bearing to sit on, which would allow it to rotate with low friction and zero noise (rumble). It must be able to support the mass of the platter and prevent run-out or eccentricity in rotation, while also allowing a shaft to continue straight through to the motor below.

More details on this to come in due course.

The 16” vacuum platter sits on top of all that and the blank disk is held securely on the platter by means of vacuum suction.

This setup has cut plenty of great sounding masters, but it will be the last one of its kind.

Since this modification was completed a few months ago, we have been developing a new, ultra high performance direct drive motor for disk recording lathes and turntables, which will be what we will use on such systems from now on. Furthermore, we are currently working on a different platter design, of even higher accuracy, while keeping the cost reasonable.

So, let’s see, we’ve got a new motor, bearing, platter, suspension, electronics…. Whats missing for a complete lathe…?

More soon..!