Absolute Polarity for Disk Records

By J. I. Agnew

https://www.agnewanalog.com

https://www.magneticfidelity.com

PDF Version

The Mystery

One might think that the whole issue of absolute polarity for a medium essentially invented around 130 years ago, would have been adequately discussed and standardised by now, leaving no room for further debates. Indeed, it has been, so why bother writing anything further on this topic?

I recently happened upon a proposed method of testing a disk reproduction system (aka vinyl record reproduction system) for absolute polarity, by dropping the stylus onto a stationary record while recording the output of the system on a digital audio workstation and observing the polarity of the impulse on the displayed waveform [1]. A long discussion ensued on which channel is meant to produce a positive output and which one is meant to be negative, with no standards being mentioned.

Subsequently, I found a few more discussions of absolute polarity, this time among people who actually cut records [2] [3] [4]. They were wondering if there were any relevant standards, defining the absolute polarity of disk records but nobody found any!

The Test Record

Eventually, a test record has become available, which includes a band of a 370 Hz asymmetric square wave with a 3:7 mark-space ratio (aka duty cycle). This is the "FloKaSon Reference Series: Testtone Record Vol.1 FSTD-001 (2016)" [5], available from Vinylike.

I received my copy long before the test record became commercially available, and decided to test it on a variety of systems. To my horror, absolute polarity was all over the place, with several reproduction cartridges being of incorrect polarity. I even came across an example of a Moving Magnet cartridge from the expensive range of a reputable manufacturer, which changed polarity when a replacement stylus assembly was fitted. This is because the orientation of the magnet defines the polarity of the generating system, so if they accidentally stick it in there the wrong way around, or as I suspect, have no clearly defined orientation at the assembly line, there will be no consistent polarity among cartridges or stylus assemblies.

But which ones are correct?

I inspected the record under the microscope, to visually verify the polarity. The grooves of disk records are visible, unlike tape magnetisation, making life much easier for the inquisitive soul. I was expecting that the 30 % pulses would be positive-going, but... they simply weren't! The 70 % pulses are positive-going on this test record! The cutting system was probably inverting somewhere. The test record is still of course perfectly usable for verifying the absolute polarity of your reproduction system, as long as you keep in mind that the 70 % shall be up and the 30 % shall be down! So the question remains: What is the standard?

How do I know that 70 % is up just by looking at it? This is defined by the standards, of which there are several, but they all fortunately agree on absolute polarity for disk records!

The Standards for Disk Records

AES26-2001 (r2011) [6]

NAB (1964) [7]

DIN 45500 (1975) [8]

IEC 60581 (1978) [9]

IEC 60098 (1987) [10]

RIAA Bulletin E1 (1954) [11]

RIAA Bulletin E2 (1957) [12]

RIAA Bulletin E4 (1961) [13]

RIAA Bulletin E3 (1963) [14]

BS 1928 (1972) [15]

BS 7063 (1989) [16]

JIS S8502 (1973) [17]

JIS C5503 (1979) [18]

JIS S8601 (1981) [19]

These are the latest versions of the standards. Earlier versions of each one exist, and several other standards may also exist, which are either mirror documents of the above, or simply not as comprehensive. The ones included in the list are the ones I have personally found most useful thus far. If you are aware of other standards that contain additional information, please do let me know.

The Problems

Part of the problem is that mastering engineers and cartridge manufacturers do not like talking to each other. I have personally tried communicating with several cartridge manufacturers, being a disk mastering engineer myself, regarding compatibility issues, and most of them refused to talk to me. The few who did, appeared to have no idea how records are made. Most did not seem interested in changing that fact. I am not only talking about cheap cartridges, by the way. I am also talking about companies claiming to be offering the ultimate cartridge at the price of a luxury car, who appear to be putting them together by chance...

Another problem is that none of the standards pertaining to disk records, their manufacturing process, and associated equipment, are actively maintained, betraying a general lack of interest in further technical innovation and standardisation, presently in the industry. However, the AES26-2001 (r2011) [6] is actively maintained and explicitly covers audio equipment polarity standardisation. Fortunately, it includes a section on disk records, specifically covering disk recording and reproducing equipment, monophonic and stereophonic, as well as all other commonly used sound recording and reproducing technologies. It was created by the Audio Engineering Society Standards Committee and was intended to cover the "conservation of the polarity of audio signals'', in accordance with several other standards.

The other standards do not explicitly mention absolute polarity, but they do cover channel phasing and orientation for stereophonic disk records, from which polarity can be inferred. As such, absolute polarity for disk records has been standardised since the very early days of stereophonic records, if not earlier. It was just not explicitly mentioned as absolute polarity. The AES26 standard, first introduced in 1995, simply pointed out the importance of polarity and collected in one document all the relevant information, mostly published elsewhere previously, presenting it in an easy to digest manner. Other polarity standards exist, but do not cover disk records, so they were not included in the list.

Absolute polarity is only preserved if it can be maintained throughout the entire process of making a recording and reproducing it. So, it won't help if your reproduction system is preserving absolute polarity according to the standards, if the record was cut on a disk mastering system that was inverting the polarity. Likewise, if the disk mastering system is preserving polarity, but the source, as in the tape machine that was used to reproduce the master tape to provide the signal to be cut, is inverting, the result will still be inverted! Fortunately, all commonly used formats are standardised [6], so it is surprisingly easy to comply.

Good Engineering Practice

I believe that all reproduction systems should be verified for absolute polarity, regardless of what "the others'' are doing. I would also like to see all professional audio facilities making an effort to comply with standards, or at least document what they are doing.

However, an industry investigation has shown that about 50 % of all recording and reproducing equipment are inverting polarity, without the user knowing. Given the current chaotic situation, I would advise anyone creating a recording and wishing to have the polarity preserved, to also record 30 seconds of an asymmetric waveform as a "test tone'', regardless of format. Do it on tape, do it on disk, do it on digital. This way, even if you are unsure about your absolute polarity, a knowledgeable engineer can verify the intended polarity and preserve it through any subsequent process. In my own disk mastering facility, I can invert the polarity of any of the sources if needed, to accommodate recordings that comply as well as those that do not comply with standards. I can check with an oscilloscope if a suitable asymmetric signal is provided, or I can just take your word for it if you have verified your system. However, if you are not sure if your recording complies with the standards and have not provided an asymmetric signal, I have no way of knowing for sure what the intended polarity was. In such cases I can only trust my ears.

Needle Drops

This brings us back to the beginning of the article, on the proposed method for verifying the polarity of a disk reproduction system by observing the polarity of the impulse generated by a needle drop. They did eventually figure out which way it should be, and this method can indeed be useful if a test record is not available. However, this method involves an A/D converter and Digital Audio Workstation: Have you verified that the ADC and DAW are actually preserving absolute polarity? If not, then you may see an inverted waveform even though your disk reproduction system was actually correctly set up, or vice versa!

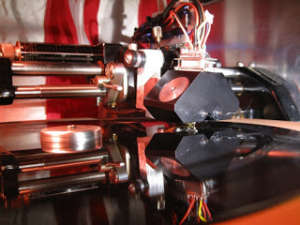

Proposed Polarity Verification Method

The most reliable method of verifying absolute polarity on a disk reproduction system is to reproduce a suitable test record of known polarity and observe the output of the preamplifier on an oscilloscope. The test record must of course include a band containing an asymmetric waveform, intended for absolute polarity verification. The correct polarity of the oscilloscope can be verified with a simple battery. Some preamplifiers might not be preserving polarity between input and output, in which case you will need to reverse the wiring on your cartridge to compensate. Cartridge wiring color coding is also covered in the standards [10]. In all cases, where the output of your preamplifier appears to be of the wrong polarity, a simple reversal of the + and - wires on BOTH channels of your cartridge will provide instant relief!

Polarity Considerations for Disk Recording Equipment

Those of you who cut records can verify the polarity of your cutting system by cutting a suitable asymmetric waveform and checking it under the microscope, or reproducing the cut on a verified reproduction system. Keep in mind that if both the cutting system and reproduction system are inverting, the polarity will appear to be correct, due to the preservation of the error and hence "relative polarity''. This is NOT an indication of correct absolute polarity.

Be careful when trying to cut an asymmetric square wave (or any squarish wave at all), as it contains harmonics extending to very high frequencies. You run a serious risk of frying your cutterhead. You could also cut a half-wave rectified sine wave instead, recommended by Paul Gold [20] and Peter Butt [21] or an asymmetric sawtooth wave as recommended by Vanderkooy/Lipshitz [22].

The articles by Butt [21] and Vanderkooy/Lipshitz [22] refer to methods of verifying the absolute polarity of magnetic tape recorders (and are in conflict with each other regarding the direction of magnetisation), but the same principles and test signals can be applied to disk records.

In any case, proceed with caution. All of the aforementioned waveforms contain a lot of harmonics and will demand considerably more current while cutting, compared to a normal sine wave. If your cutting system is not correctly set up, such signals could excite resonances causing self-oscillation, which means expensive damage! All such testing shall be done entirely at your own risk. You have been warned!

Some Neumann amplifier racks are known to invert polarity. The FloKaSon Caruso preamplifier is inverting polarity. If the cutting amplifier is also inverting and the head is correctly wired, the result will be correct. The Agnew Analog Reference Instrument Type 891 cutting amplifier [27], which I have developed, is preserving polarity, so if used with the Caruso preamplifier and a correctly wired head, the result would be inverted. To avoid that, you can invert the wiring to the cutterhead (both drive coils and feedback coils on both channels). The result will then be in accordance with the standards. On the other hand, the Agnew Analog Reference Instrument Type 710 disk recording pre-emphasis module is preserving polarity as well, so if used with the Type 891 or any other cutting amplifier which preserves polarity, the wiring to the cutterhead shall be configured in the standard manner to preserve polarity on the resulting disk.

If you are monitoring the feedback signal, keep in mind that this is meant to be inverted at some point, relative to the cutting amplifier output signal, it is NEGATIVE feedback! On the Caruso preamp, the output to the cutting amplifier is inverted relative to the input, and the feedback monitor signal is of opposite polarity to the output. Therefore, the signal at the feedback monitor output should be of the SAME polarity as the program material input, provided that the cutterhead is correctly wired and labeled. The correct wiring of the cutterhead depends on whether the cutting amplifier is inverting or not.

Each make and model of cutting electronics is designed differently, so you will need to do some figuring out, when putting together a disk mastering system.

Also keep in mind that your microscope might be inverting the image and that on most lathes it is located at the opposite side of the disk. Once you manage to orient yourself, it should be easy to confirm the polarity visually.

The Definition of Absolute Polarity for Disk Records

According to all the standards, a positive signal voltage applied to both channels of a stereophonic system, or a monophonic system, shall produce an outward lateral motion of the cutting stylus, away from the centre of the disk, towards the rim.

Consequently, an outward lateral motion of the reproduction stylus shall produce a positive-going voltage at both channels of a stereophonic reproduction system.

But is it audible?

Absolutely [23] , a lot of real life sounds cause asymmetric variations in air pressure [24] and our hearing mechanism is quite sensitive to this [25] Other perception mechanisms may also contribute, under certain conditions. As such, there is no question about the importance of preserving absolute polarity in our recordings [26] . The information is easily stored in recorded form, on all media. The audibility upon reproduction will obviously depend on the ability of the reproduction system to preserve and present this information without too much loss. Even for systems not adequately detailed to enable the listener to clearly perceive the effect of a polarity inversion, no harm is done by preserving the polarity. On systems where the difference is audible though, an unnecessary deviation from the intended auditory experience would be introduced if absolute polarity has not been maintained.

Conclusion

Admittedly, with the exception of pointing to a suitable, recently produced test record, and the discussion on some recently introduced equipment for disk recording, most of the information presented in this article is nothing new. Given the circumstances, however, collecting this under one roof, in a publicly accessible article, seemed like a good idea, to help preserve the knowledge and hopefully stimulate renewed interest in the correct application of the technology by manufacturers of records and record manufacturing or reproducing equipment, as well as the correct use of the technology by the discerning listener, to rediscover the true potential of the medium.

Acknowledgements

I would like to thank Sabine Agnew for tirelessly editing my notes into something readable, as well as the engineers and organisations who participated in standardisation efforts, passing on to subsequent generations the cultural heritage of a great body of recorded sound in an internationally accepted and standardised format. Special thanks are also due to Flo Kaufmann, of FloKaSon, Switzerland, for the several interesting discussions, for producing the test record and for designing some of the equipment that inspired me to write this article.

References

[1] back2vinyl, “Finally - an absolute polarity test for vinyl playback,” Steve Hoffman Fo-

rum, 2015 (Retrieved on January 10, 2018).http://forums.stevehoffman.tv/threads/finally-an-absolute-polarity-test-for-vinyl-playback.473528/.

[2] markrob, “Absolute Polarity,” The Secret Society of Lathe Trolls Forum, 2011 (Retrieved on January 10, 2018). https://www.lathetrolls.com/viewtopic.php?f=11&t=2573.

[3] W. Kirkwood, “Vinyl Polarity Relationships in the Westrex 45/45 Systems,” The Secret Society of Lathe Trolls Forum, 2016 (Retrieved on January 10, 2018). https://www.lathetrolls.com/viewtopic.php?=1&t=6661.

[4] richard ec2, “When cutting a record, which channel has inverted polarity?,” The Secret Society of Lathe Trolls Forum, 2015 (Retrieved on January 10, 2018).https://www.lathetrolls.com/viewtopic.php?f=1&t=5526.

[5] FloKaSon, “FloKaSon Reference Series: Testtone Record Vol.1 FSTD-001,” 2016.

[6] AES, “AES recommended practice for professional audio - Conservation of the polarity of audio signals (Revision of AES26-1995),” Tech. Rep. AES26-2001(r2011), Audio Engineering Society Inc., May 2011.

[7] NAB, “NAB Audio Recording and Reproducing Standards for Disc Recording

and Reproducing,” National Association of Broadcasters, 1964.

[8] DIN, “Hi-fi Technics - Requirements For Disk Record Reproducing Equipments,”Tech. Rep. DIN 45500, Deutsches Institut für Normung, 1975.

[9] IEC, “High fidelity audio equipment and systems: Minimum performance requirements,” Tech. Rep. IEC 60581, International Electrotechnical Commission, Jan. 1978.

[10] IEC, “Analogue audio disk records and reproducing equipment,” Tech. Rep. IEC60098, International Standards Commission, 1987.

[11] RIAA, “Standard Recording and Reproducing Characteristic,” Tech. Rep. RIAA Bulletin E1, Record Industry Association of America Inc., 1954.

[12] RIAA, “Dimensional Standards of Disc Phonograph Records,” Tech. Rep. RIAA Bulletin E2, Record Industry Association of America Inc., 1957.

[13] RIAA, “Standards For Stereophonic Disk Records,” Tech. Rep. RIAA Bulletin E3, Record Industry Association of America Inc., Oct. 1963.

[14] RIAA, “Dimensional Standards: Disc Phonograph Records For Home Use,” Tech. Rep. RIAA Bulletin E4, Record Industry Association of America Inc., Oct. 1963.

[15] BSI, “Specification for processed disk records and reproducing equipments,” Tech. Rep. BS 1928, British Standards Institution, Committee EPL/100, Jan. 1972.

[16] BSI, “Specification for analogue audio disk records and reproducing equipment,” Tech. Rep. BS 7063, British Standards Institution, Committee EPL/100, Feb. 1989.

17] JSA, “Disk Records,” Tech. Rep. JIS S8502, Japanese Standards Association, 1973.

[18] JSA, “Phonograph Pick-Ups,” Tech. Rep. JIS C5503, Japanese Standards Association, 1979.

[19] JSA, “Disk Records,” Tech. Rep. JIS S8601, Japanese Standards Association, Jan. 1981.

[20] P. Gold, “When cutting a record, which channel has inverted polarity?,” The Secret Society of Lathe Trolls Forum, 2015 (Retrieved on January 10, 2018). https://www.lathetrolls.com/viewtopic.php?f=1&t=5526#p33887.

[21] P. Butt, “A Proposed Method for Uniform Determination of Polarity Response of Magnetic Reproducers,” in Audio Engineering Society Convention 66, May 1980. http://www.aes.org/e-lib/browse.cfm?elib=3724.

[22] J. Vanderkooy and S. P. Lipshitz, “Polarity and Phase Standards for Analog Tape Recorders,” in Audio Engineering Society Convention 69, May 1981. http://www.aes.org/e-lib/browse.cfm?elib=11959.

[23] S. P. Lipshitz, M. Pocock, and J. Vanderkooy, “On the Audibility of Midrange Phase Distortion in Audio Systems,” J. Audio Eng. Soc, vol. 30, no. 9, pp. 580–595, 1982. http://www.aes.org/e-lib/browse.cfm?elib=3824.

[24] W. L. Hetrich, “Real-World Audio Wave Form Asymmetries and the

Effect on the Audio Chain,” in Audio Engineering Society Convention 55, Oct 1976. http://www.aes.org/e-lib/browse.cfm?elib=2221.

[25] M. R. Schroeder, “Models of Hearing,” Proc. IEEE, vol. 63, pp. 1332–1350, Sept 1975.

[26] P. Copeland, “Manual of Analogue Sound Restoration Techniques,” The British Library, pp. 22–23, 2008.