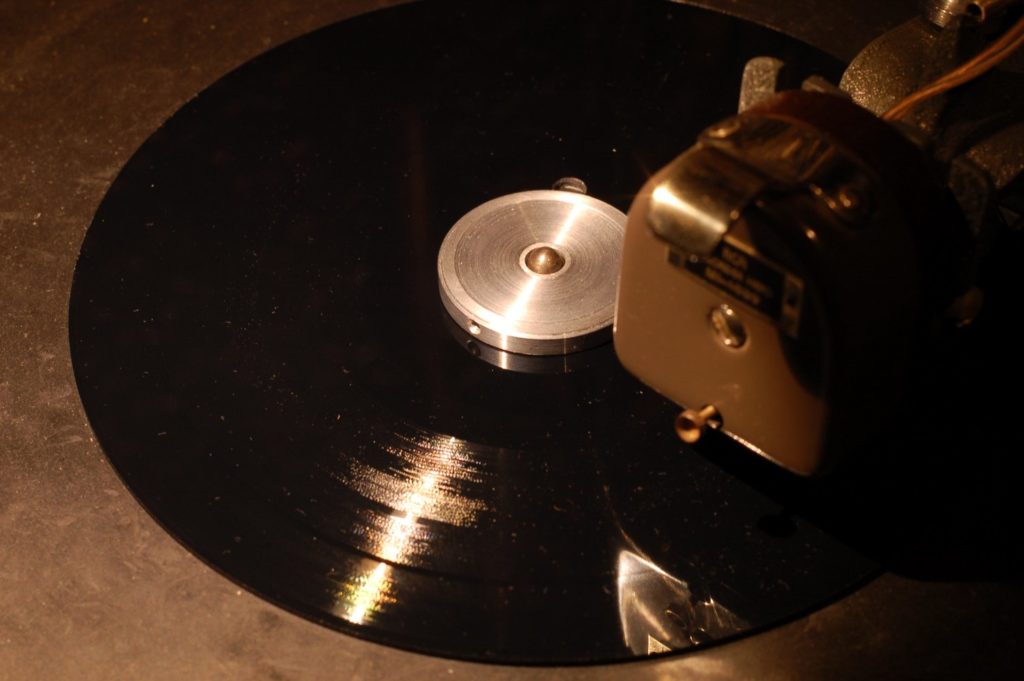

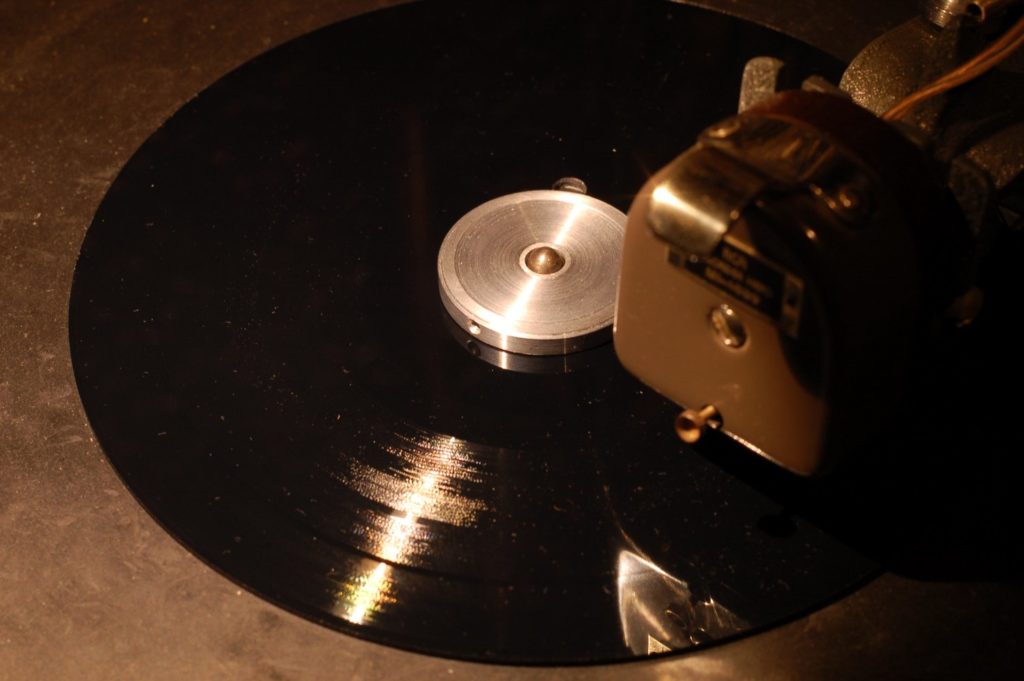

A low profile record clamp for disk recording lathes

The Type 6079 is our new low profile record clamp, for securely holding the blank disk in place on a disk recording lathe, during the cutting operation.

Agnew Analog News

The Type 6079 is our new low profile record clamp, for securely holding the blank disk in place on a disk recording lathe, during the cutting operation.

A customer recently imported a vintage Presto 75A disk recording lathe from the USA, with a view to cutting records in Europe.

He quickly discovered, like many people before him, that it was spinning a bit slower than it should, when operated from 50 Hz mains, via a simple step-down transformer. As with most vintage record cutting machines, the platter is powered by a synchronous AC motor, which "locks" to the line frequency.

It would appear that 50 Hz conversions of vintage "made in USA" disk recording lathes are becoming rather fashionable! Last week we examined how we converted a Rek-O-Kut Model V by machining a new capstan and making a special transformer, Type 1760.

We have done 50 Hz conversions (and even some 60 Hz ones!) on many different lathes and turntables, using all of the possible methods of doing so: New rubber rollers, new capstans, new belt pulleys and even electronic frequency conversion (Agnew Analog Type 191 frequency converter) for professional disk mastering systems.

This week, we will have a look at the Presto 75A, a high quality machine, dating from the 1930's, which was even used by the BBC as a broadcasting turntable!

Depicted here, are two external rotor, polyphase, electronic commutation motors, fitted to custom mounting plates, ready to be installed in disk recording systems, to control the leadscrew.

These are very high precision motors, with features allowing accurate, closed-loop control of speed over a wide range, as well as positioning applications. A combination of hall sensor arrays and high resolution encoders makes them extremely versatile, compatible with a wide range of lathes.

Our popular range of premium transformers and iron-core inductors just got prettier!

No need to hide your transformers!

With powder coated end-bells in Agnew-cream-white and our fancy engraved stainless steel product plates riveted on, with type designation and serial number stamped by hand as a seal of approval following our extensive testing and quality control procedures, our transformers now look as good as they are!