New Hydrodynamic Oil-bath Bearing Units Available Now!

For many long years, J. I. Agnew has been examining, adjusting, repairing and replacing bearing systems of all kinds, from disk recording lathes and turntables to tape machines, high precision machine tools, measurement instruments, industrial equipment and all manners of motor vehicles, from passenger cars to heavy trucks. Over the past few years, he has designed and machined countless bearing units to replace worn or damaged units on a diverse range of disk recording lathes and machine tools. Valuable experience was gained, which along with his solid engineering background, was put to good use in improving his designs further and further, up until the current stage of development was reached.

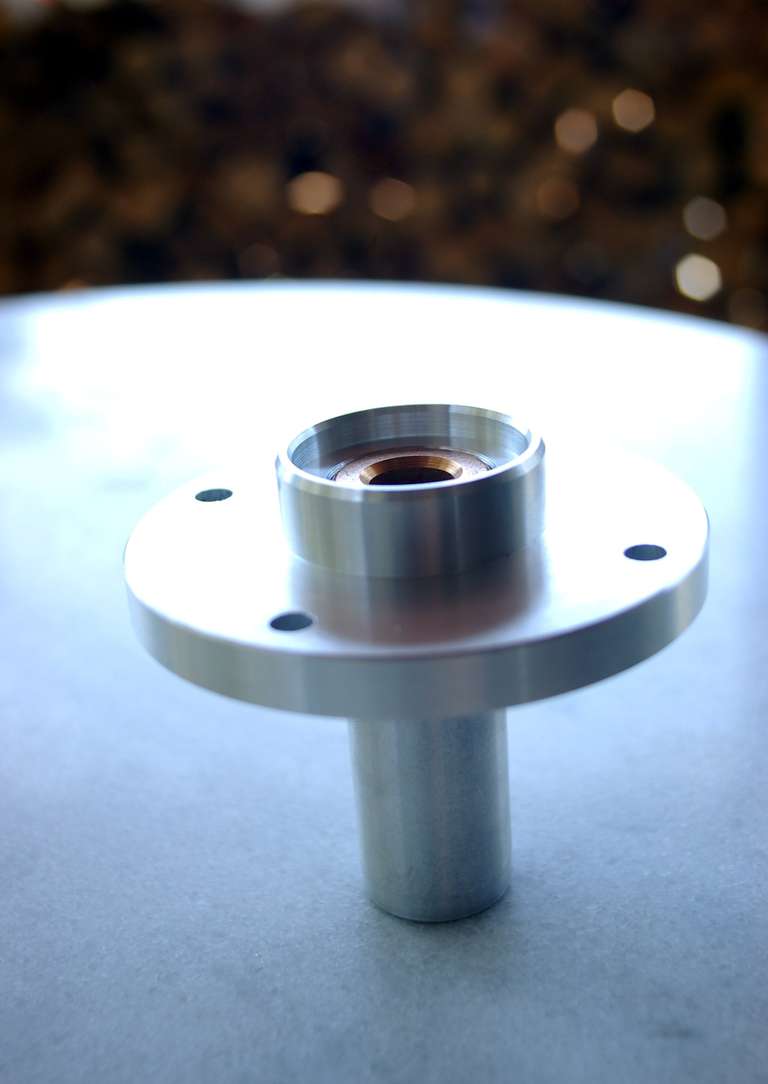

We now have an extremely reliable hydrodynamic bearing unit of our own design, where the spindle operates in an oil bath and is effectively floating on a film of oil while spinning, eliminating metal-to-metal contact. The result is an extremely accurate bearing unit with vanishing low noise, that can be used to seriously upgrade the performance of any make and model of lathe of any vintage. We have used these bearings to convert Scully lathes to direct-drive, along with our vacuum platters (Type 6114 and Type 6112) and direct-drive motors (Type 631 and Type 632). Not only the old Scully 501/601 lathes, but also the LS-76. We have also used them to upgrade Presto 14B and 8DG lathes, as well as the Fairchild 539 and 199. They have proven themselves in the field and have even been used as an upgrade on Neumann lathes.

Our hydrodynamic bearing design has reached full maturity and is now available with a suitable mounting arrangement to fit any lathe you may have. Tired of trying to get your SL1200 to behave on your T560? Now you can finally throw it out and install a real vacuum platter with a bearing unit actually designed for cutting records.

The Type 6312 bearing unit is designed to be driven from below, with a floor standing high performance direct drive motor being the recommended configuration. We can supply the entire drivetrain, from the direct drive motor and driveshaft (machined to any length and diameter required) to the bearing unit, shaft, subplatter and vacuum platter.

Ready to take your vintage lathe to the next level? Contact us with your requirements.