Agnew Analog News

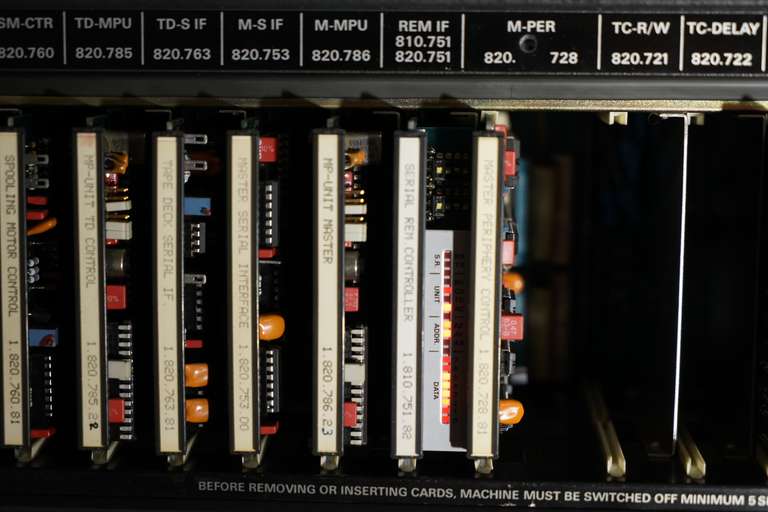

Agnew Analog Type 223 Lathe Pitch Control Unit

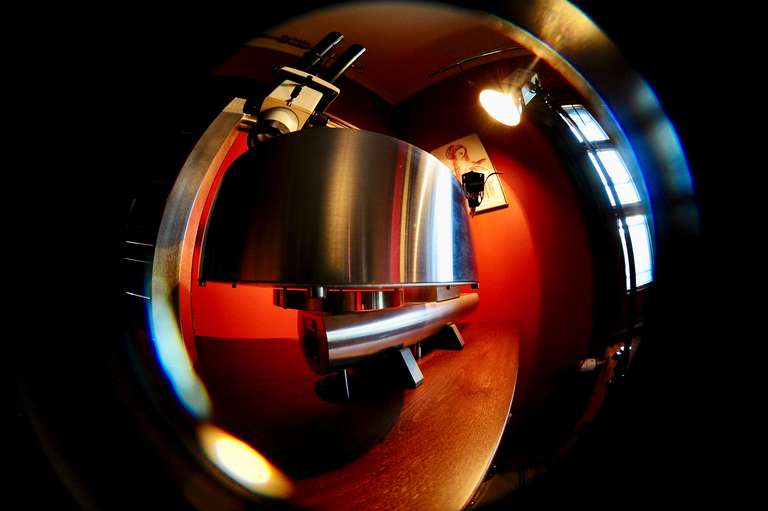

The Agnew Analog Type 612P Reference Disk Record Reproducer

A legacy, designed to outlive its creators. Proudly handcrafted to pass on to the next generations along with a rich cultural heritage of sound, forever captured in modulated record grooves. Preserving a long tradition of precision engineering and fine craftsmanship, Agnew Analog proudly presents the ultimate reference turntable.

Cutting records by the sea...

Off Grid Energy and Communications Systems

Introducing Glasgow Analog

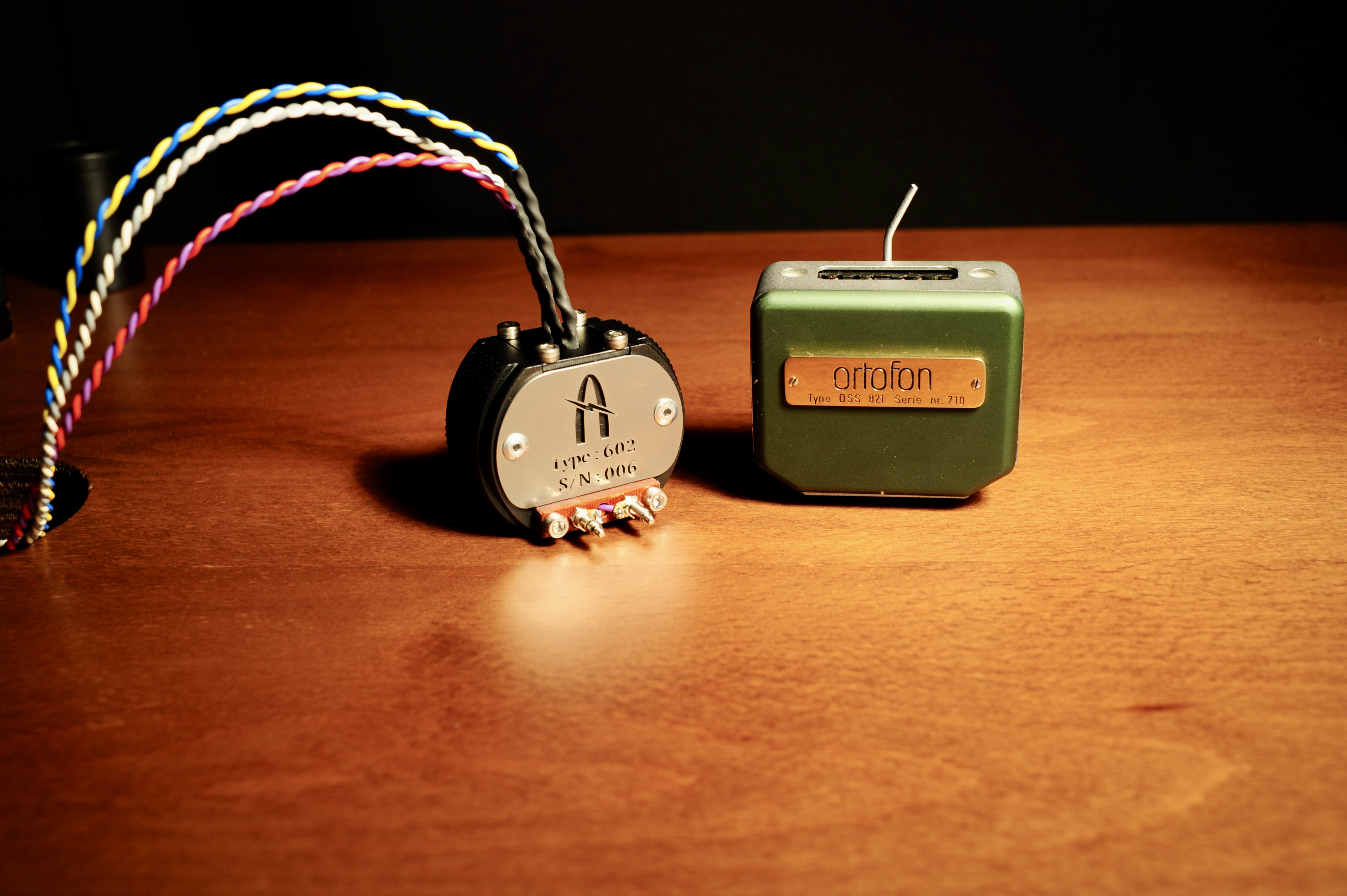

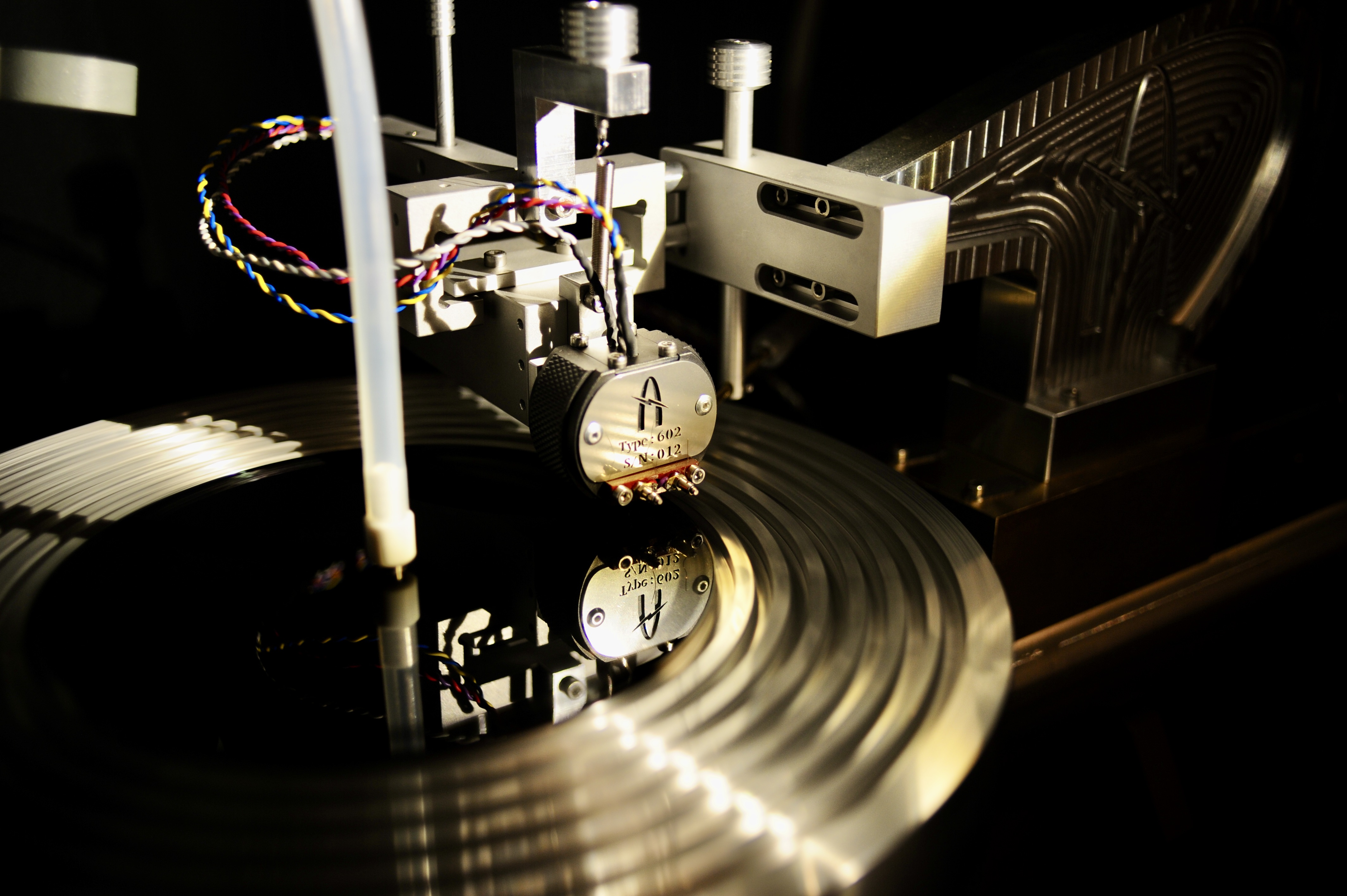

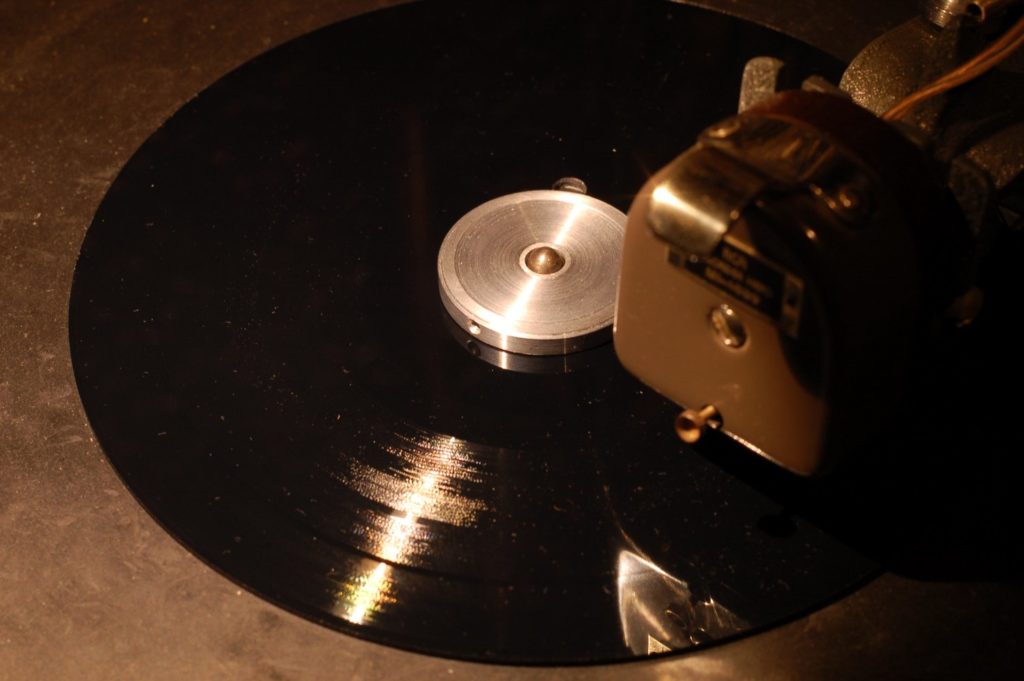

The Agnew Analog Type 602 next to the Ortofon DSS 821

The new Agnew Analog Type 602 Stereophonic Cutter Head next to a vintage Ortofon DSS 821 Stereophonic Cutter Head, as a dimensional reference.

Agnew Analog Reference Instrument Type 602: A new Stereophonic Cutter Head.

Wally Analog Visits Agnew Analog

J.R. Boisclair of WAM Engineering LLC, the manufacturers of the WallyTools Analog Setup Tools, from Santa Rosa, CA, flew over to Greece to tour the Agnew Analog Precision Engineering Laboratory and discuss highly technical topics with J. I. Agnew. We had the great pleasure of using the WallyTools to set up the turntable at the Agnew Mansion and will be writing more about these in a dedicated post soon! The visit wouldn't be complete without a walk by the beach and some fine Greek cuisine. Stay tuned for more exciting news! Photography by Kate Agnew.

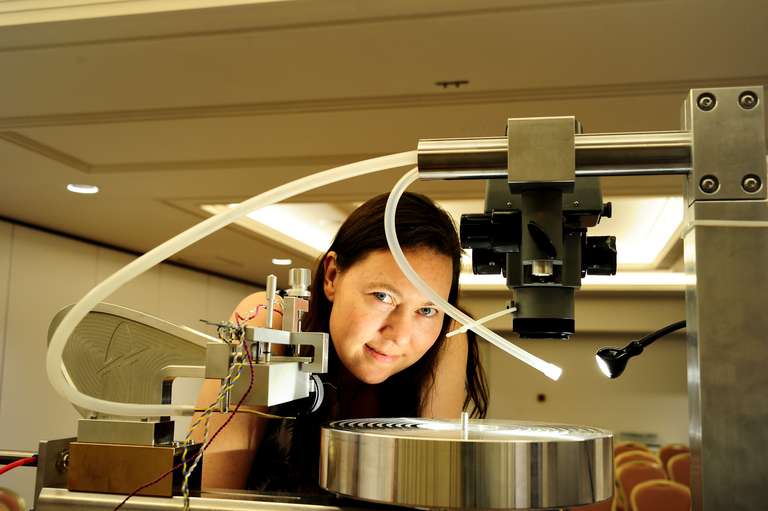

Agnew Analog Reference Instrument Type 612: A new Disk Mastering Lathe

After many long years of research and development and long field testing of the various components, we are proud to present the Agnew Analog Reference Instrument Type 612, a brand new disk mastering lathe, now available to order.

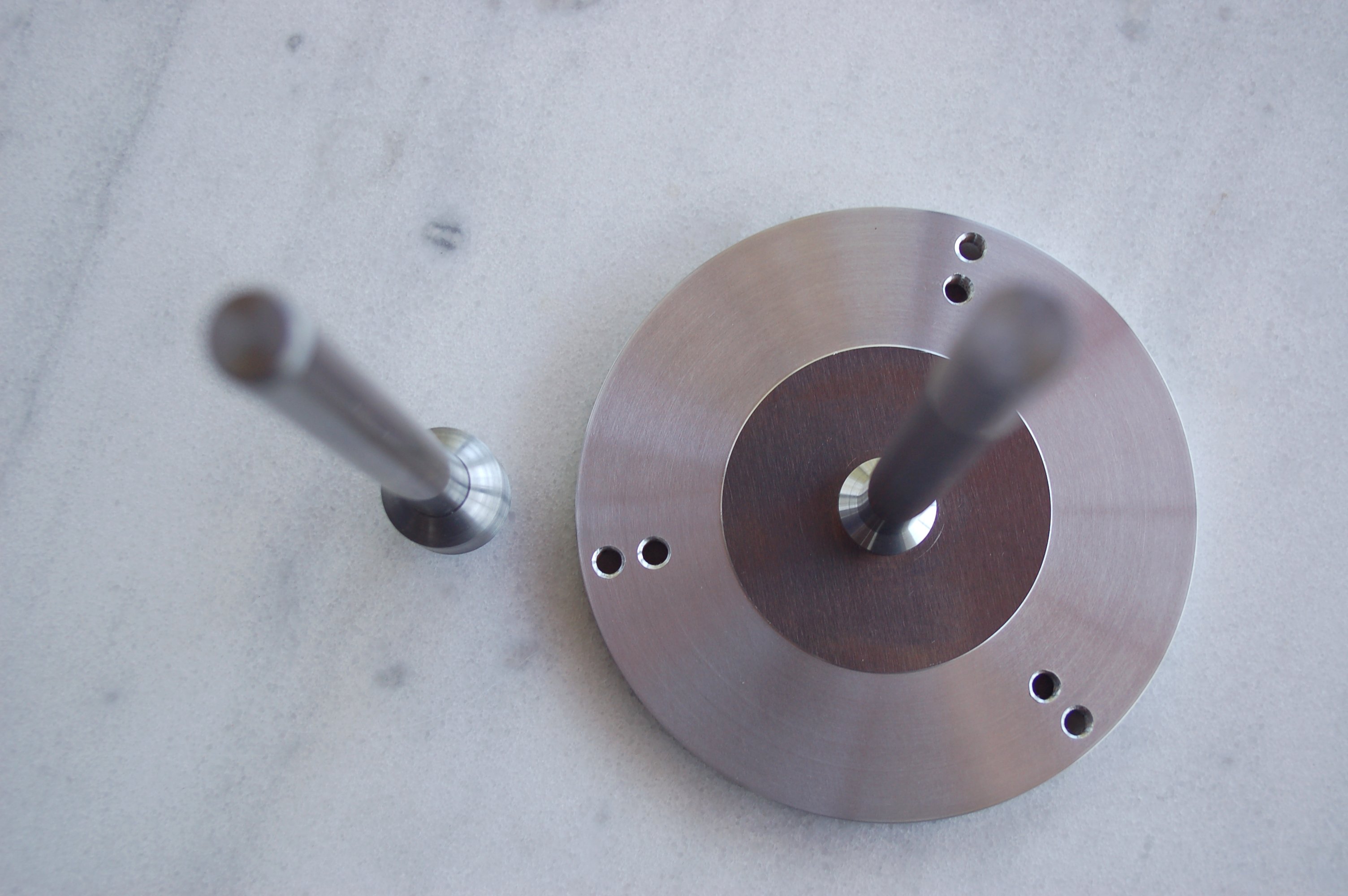

Precise vinyl record centering for turntables

Presenting a custom record centering accessory, intended as a very quick and simple way of centering vinyl records with oversize center holes.

This compact and lightweight accessory is simply placed on the center spindle of your turntable over the record and twisted, positioning the sharp edge between the spindle and record hole, taking up any excessive clearance.

Agnew Analog Type 6016 Scribing Platform

The Agnew Analog Reference Instrument Type 6016 is a fully adjustable scribing platform that will work on any make and model of lathe of any vintage, with a 16", 14", or 12" platter, for 14", 12". 10" or 7" records. Scribing platforms are typically used by mastering engineers, to rest their hand while scribing the catalog number, their signature, or secret messages, in the land around the lead-out groove spiral, without touching the surface of the fragile lacquer master disk. Remember, it is your signature that should be proudly displayed on that master disk, not your fingerprints! Significant quantity discounts available, especially on orders over 100 pieces. Please enquire for details.

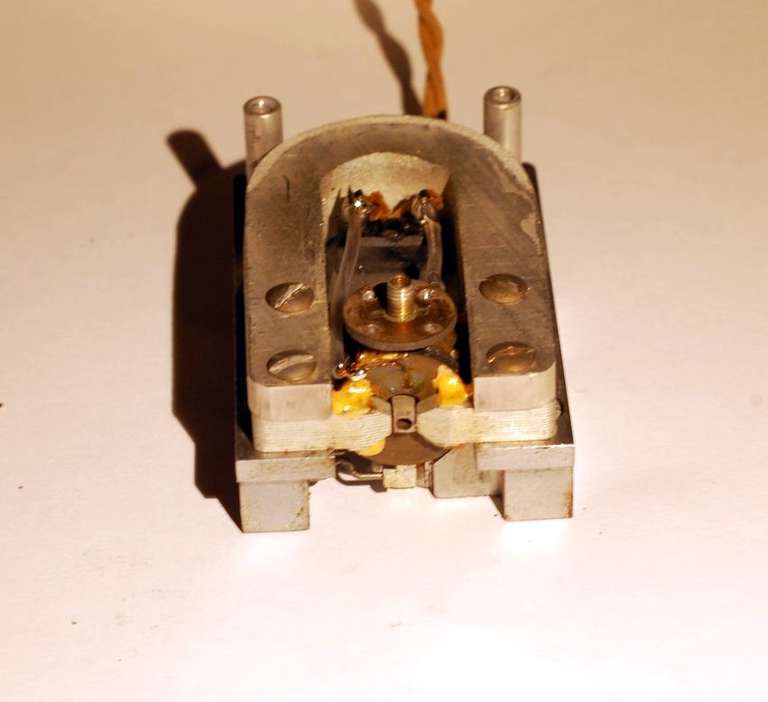

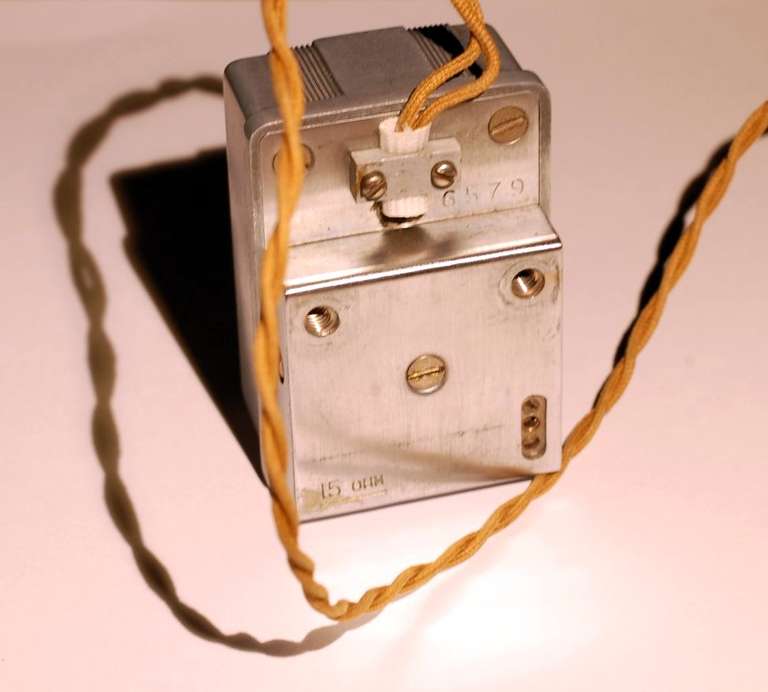

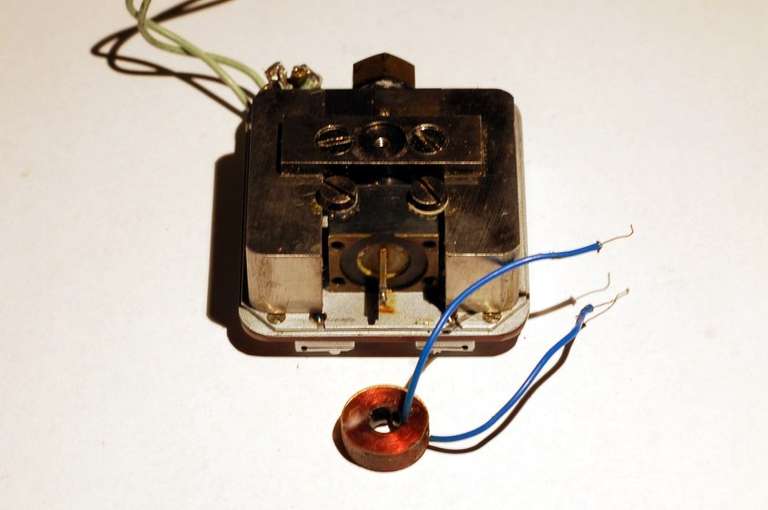

SA-74 Suspension Unit Repair From Neumann VMS-70 Disk Mastering Lathe

Repairing an SA-74 suspension unit, from a Neumann VMS-70 disk mastering lathe, which arrived with the head lift/drop lever jammed in the down position, preventing the top lid from being removed! The Neumann SX-74 stereophonic motional feedback cutter head was still attached, as it had been glued to the mount adapter, which can only be removed from the suspension unit by opening the top lid! Several mechanical and electrical repairs, adjustment/calibration procedures and even a bit of machining on the 1961 Moore Special Tools Jig Borer later, it was fully brought back to original specifications!

J.l. Agnew will be speaking at Craft Research Network event!

As part of the 5th Craft Studio event, held online via Zoom and organized by the Craft Research Network, J.l. Agnew will be holding a presentation of his work at the Agnew Analog Precision Engineering Laboratory. The event is scheduled for Friday, September 16, 2022, at 17:00 CET. Registration (free of charge) at least a week in advance of the event is required for participation. Registration form: https://craftresearch.org/join The Craft Research Network is an international, multidisciplinary research network for academics and others with an interest in craft. Craft Studio 5 is hosted by Rene Wiedner (Associate Professor, University of Warwick, UK) and Marleen Hofland-Mol (PhD Candidate, Erasmus University, Rotterdam, NL).

Agnew Analog Type 631 Direct Drive Motor and Type 231 Control Module

The Agnew Analog Reference Instrument Type 631 is a high performance direct drive motor, designed for professional disk mastering lathes and turntables. It is usually positioned on the floor under the lathe or turntable, driving the platter directly by means of a long driveshaft, similar to the drive system of the Neumann VMS-70 and several other professional disk mastering systems.

Repairing a Westrex 2B cutter head

Some time ago we were asked to repair a vintage Westrex 2B feedback cutter head.

As with all Western Electric and Westrex products, their cutter heads were beautifully made and represented the state of the art in their time. Not only did they sound great, they also looked aesthetically pleasing, with curved lines that were not a trivial task to manufacture, in the days before CNC machine tools, CAD software and pocket calculators!

New Series 6500 Driveshafts now available

We have developed a range of precision machined driveshafts that can be supplied in any length required for your applications, with end diameters to your specification. Each end could be made a different diameter, if required, and we can also supply a useful range of accessories, such as constant velocity flexible couplers, vibration dampers, soft-start clutches and mounting flanges, to suit your application.

New line of high precision machine spindles now available

A good machine spindle is one of the factors defining the accuracy attainable from rotating machinery. This applies equally to machine tools used in industrial manufacturing and to disk recording and mastering lathes, used to make phonograph records.

At Agnew Analog Reference Instruments, we use some of the finest and most accurate industrial manufacturing machine tools ever made, to build some of the finest and most accurate disk recording and mastering equipment ever made, so we have had to learn a thing or three about machine spindles along the way.

New Hydrodynamic Oil-bath Bearing Units Available Now!

For many long years, J. I. Agnew has been examining, adjusting, repairing and replacing bearing systems of all kinds, from disk recording lathes and turntables to tape machines, high precision machine tools, measurement instruments, industrial equipment and all manners of motor vehicles, from passenger cars to heavy trucks. Over the past few years, he has designed and machined countless bearing units to replace worn or damaged units on a diverse range of disk recording lathes and machine tools. Valuable experience was gained, which along with his solid engineering background, was put to good use in improving his designs further and further, up until the current stage of development was reached.

New Series 6100 Vacuum Platters

The ultimate vacuum platter is finally here, and it is very reasonably priced. After three years of exhaustive research and development and several prototypes of different versions, along with field testing, we have finally arrived at what we believe is the most advanced and accurate vacuum platter ever made.

Available in 14" and 12" versions, our Type 6114 and Type 6112 Reference Instruments are now available to order, in any quantity. Do you want 100 of them? We'll make them, and threw in a quantity discount as well!

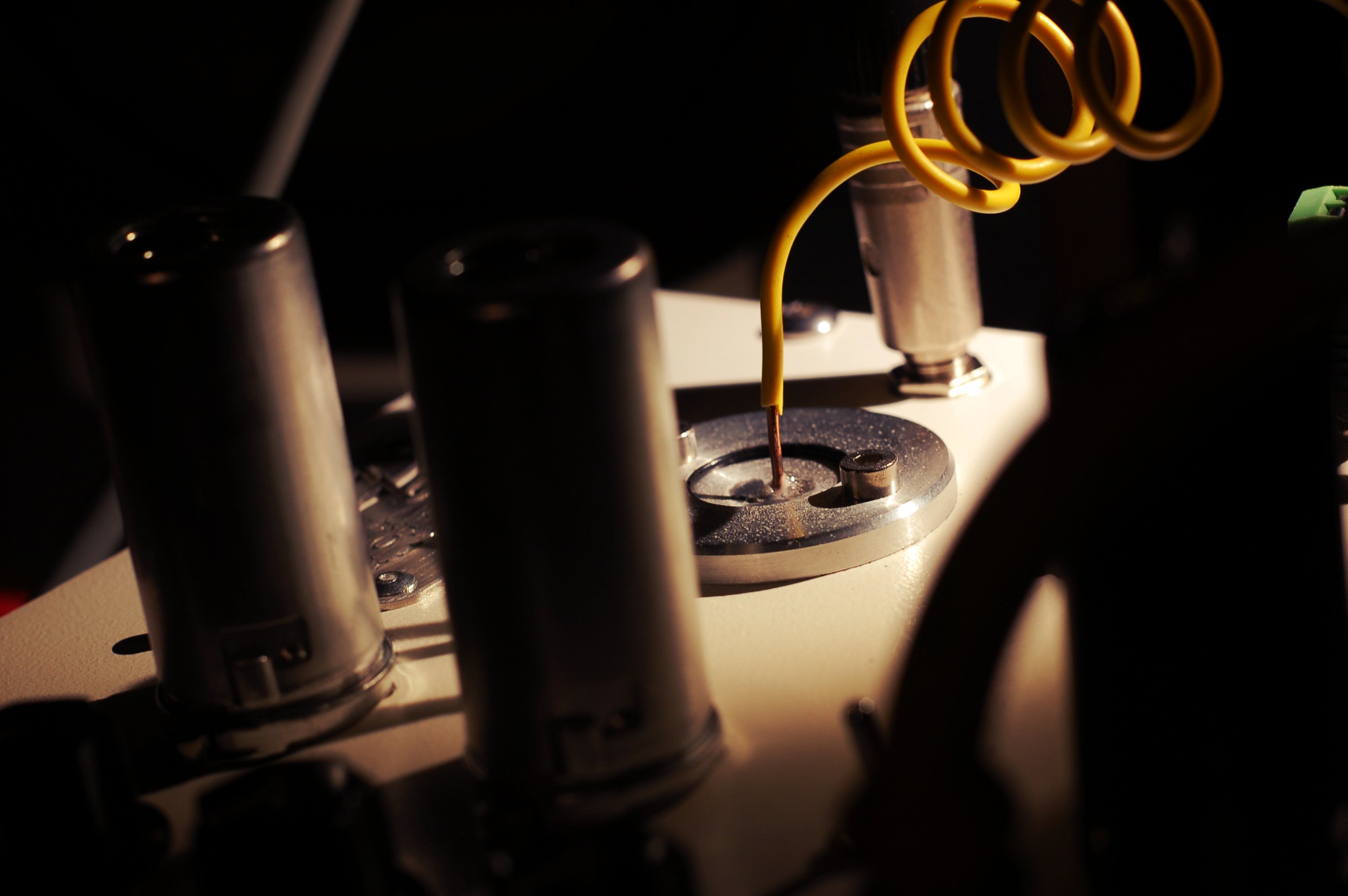

Heater Wire Terminals

The Reliable Stylus Heating System: Type 192

The Agnew Analog Reference Instrument Type 192 is a minimalist, industrial-grade stylus heater supply unit, designed and built to last forever.

It is a current-regulated design, set at the factory for 550 mA, in an ultra-ruggedized configuration, for maximum reliability in constant-duty environments, when downtime is not an option.

The Vacuum Tube Electrochemical Synthesizer: Type 8001

The Agnew Analog Research and Development laboratory makes a major breakthrough in the fight against the SARS-CoV-2 pandemic!

It is not a vaccine and it probably won’t do much against the virus itself (although it has been suggested that it could have an effect not unlike the yodeling of Slim Whitman upon the aliens in Tim Burton’s “Mars Attacks”, either on the virus or on humans, or both), but will at least give you something to do while you wait it out.

The Agnew Analog Reference Instrument Type 8001 is a unique electrochemical synthesizer, generating strange sounds through chemical reactions occurring in the built in reactor cell.

Westrex 2B Stylus Adapter

The Westrex 2B is a motional feedback cutter head, introduced in 1952 by the Western Electric Export Company. It followed hot on the heels of the Westrex 2A, dating from 1947, which was itself a lateral implementation of the principles first described by Wiebusch, Vieth and Yenzer in 1938, with a couple of relevant patents issued by 1939, for a vertical cutter head employing motional feedback.

Direct-Drive Conversion on a Fairchild Lathe

The Fairchild line of disk recording lathes, first appearing in the early 1930’s, featured a General Electric hysteresis synchronous AC motor, running at high speed, with a worm and gear reduction to drive the platter. While this system in its various permutations in their different models was impressively well made and performed well for its time (see here for a more detailed description and pictures), a direct-drive system with a floor mounted motor is clearly the way to go if the highest level of performance is to be attained.

Type 1501 Stylus Shank Adapter gets a Flat!

Our popular Agnew Analog Reference Instrument Type 1501 Stylus shank adapter was intended to make it possible to use the Neumann-style taper shank stylus (Transco 320, Adamant NSH-2, etc) with vintage mono heads such as the Presto 1-C and 1-D, which need a long shank stylus.

Up to now, customers would just install the adapter and leave it there, only occasionally replacing the stylus. One customer, however, wanted to be able to leave the stylii aligned in the adapter, and change them out without needing to realign.

Testing Directly-Heated Triodes

In the darkest corner of the catacombs under the lab, illuminated only by glowing directly-heated triode filaments, top secret experimental research is being conducted…

Presto 1-D Cutter Head Feedback Modification

Presto 1-D and 1-C cutter heads are frequently encountered on our lab bench for repair and restoration. Some are just regular repairs to original spec, others are rewound to a different impedance, but some undergo more comprehensive and exciting modifications!

We have previously examined modifications where a feedback system was added to a Neumann MS-52H and an Audax R-56 cutter head. This time, we shall discuss adding feedback to a Presto 1-D, which arrived with damaged coils.

Rebuilding an Audax R-56 Cutter Head with Feedback

This Audax cutter head arrived with a fried coil and a completely crusted armature. The damping material had not aged well.

A complete disassembly, cleanup and reassembly would be required, with the renewal of the damping material and drive coil. This was yet another perfect candidate for our feedback modification.

Fitting a Neumann Cutter Head to a Presto Lathe

Neumann cutter heads have a rib along the back, for mounting. Presto lathes, on the other hand, together with the vast majority of non-Neumann vintage lathes (Rek-O-Kut, Fairchild, etc.), have a mount with two slots, for cutter heads with two threaded holes on the back (Audax, Presto, Fairchild, RCA, etc).

Neumann MS-52H Cutter Head with Feedback: Repair and Hot Mods

The second issue was that the original stylus fitting was broken.

A Fashionable Rek-O-Kut Lathe Cabinet

Have you ever noticed the total absence of audio equipment from the luxury houses presented in glossy architecture and interior design magazines? It makes the inhabitants of such property come across as rather uncultured.

In fact, not only is an audiophile grade sound system a minimum requirement for the home of anyone affluent enough to hire an interior designer, but it is important to choose a designer who can appreciate the aura of sophistication and intellect projected by a beautifully restored vintage disk recording lathe, set in a handcrafted custom cabinet, in a conspicuous corner of the living room!

RCA reaches 100 Years of Age!

One hundred years ago, on October 19, 1919, RCA was founded. Among countless other things, they made some amazing ribbon microphones, several disk recording lathes, a few different cutter heads and some of the best sounding vacuum tubes, many of which are still in regular use to this day.

School of Cut - Learning how to cut records at Agnew Analog

We recently had the pleasure of having Symatic over, from Bristol, UK, for a week of training on how to cut (and how not to cut) records. Symatic also performs with the Skratchlords around the world. For further information, please visit the links below: Cut & Paste Records Skratch Lords documentary Youtube Skratch Lords Community facebook

The Stylish Stylus Tool

Requests for a stylus tool kept on coming in, so we decided to design and manufacture them! We call it the Agnew Analog Reference Instruments Type 6019 and it is now available for sale.

Hardinge HLV Super-Precision Lathe Restoration: Variable-Speed Drive

All Hardinge HLV and HLV-H variants feature a continuously variable speed drive to the spindle. It starts with a 3-phase, two speed squirrel cage induction motor, rated at 500 rpm and 1500 rpm nominal (less in practice, due to slip) at 50 Hz. This would be 600 rpm and 1800 rpm at 60 Hz.

Restoring a 1954 Hardinge HLV Super Precision Toolroom Lathe: The Carriage

Finding a Hardinge HLV can be challenging enough, especially if, like us, you happen to be located in Europe. At 1400 lbs, shipping and handling gets complicated. In a previous post, we described the joys of forklifting the beast onto a platform trolley (with suitable structural support added to the building), to get it to the workshop, though narrow corridors and doorways. Once there, it had to be lifted off the trolley and placed directly on the floor. With no chance of being able to drive the period-correct forklift truck into the shop, we had to get creative. A hydraulic engine hoist along with slings and tacks got the job done neatly. With the lathe on the floor and properly leveled, it was time to check it over, replacing, adjusting, lubricating and cleaning parts along the way!

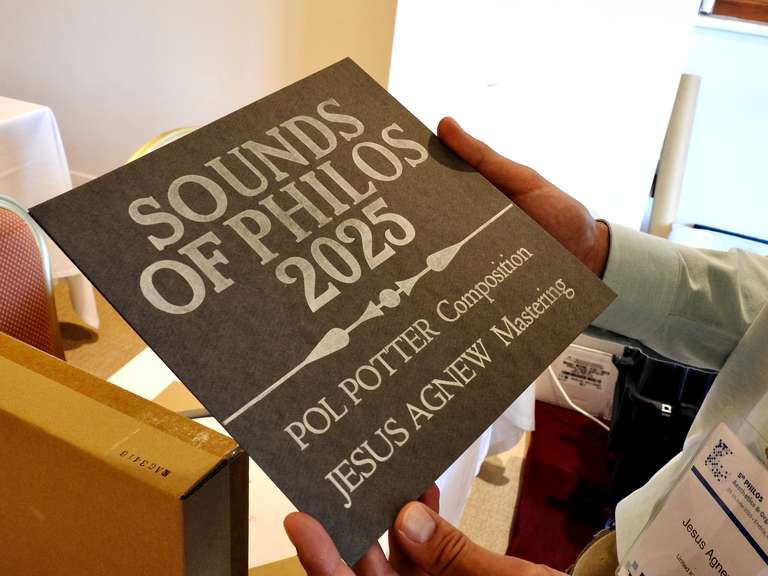

Rocky Mountain International Hi-Fi Press Awards 2019: Naxatras III voted Best Audiophile Recording!!!

Rek-O-Kut Master Pro System with modified Presto 1D Cutter Head

It consists of a Rek-O-Kut Model V 16" turntable, which he found in the USA (where else?) as a non-runner. The motor was in bad shape and refused to run at all. Even if it would run, it was expecting to be fed on a regular diet of 110 VAC/60 Hz!

A new vintage lathe in the shop: The Hardinge HLV!

The best finds always pop up in the summer, when everyone else is on holidays! Still, they are not always nearby or easy to deal with. When this 1954 Hardinge HLV precision toolroom lathe appeared on the horizon, it took all of 5 minutes to decide to go for it and one week of frantic international phone calls to organize everything. An engineer was sent to check it over, local transportation to an industrial machinery crating facility, international transportation, more local transportation and another week later it was finally in our yard!

A low profile record clamp for disk recording lathes

The Type 6079 is our new low profile record clamp, for securely holding the blank disk in place on a disk recording lathe, during the cutting operation.

Presto 75A Restoration Project

A customer recently imported a vintage Presto 75A disk recording lathe from the USA, with a view to cutting records in Europe.

He quickly discovered, like many people before him, that it was spinning a bit slower than it should, when operated from 50 Hz mains, via a simple step-down transformer. As with most vintage record cutting machines, the platter is powered by a synchronous AC motor, which "locks" to the line frequency.

Presto 75A: 50 Hz 33 1/3 and 45 rpm Conversion

It would appear that 50 Hz conversions of vintage "made in USA" disk recording lathes are becoming rather fashionable! Last week we examined how we converted a Rek-O-Kut Model V by machining a new capstan and making a special transformer, Type 1760.

We have done 50 Hz conversions (and even some 60 Hz ones!) on many different lathes and turntables, using all of the possible methods of doing so: New rubber rollers, new capstans, new belt pulleys and even electronic frequency conversion (Agnew Analog Type 191 frequency converter) for professional disk mastering systems.

This week, we will have a look at the Presto 75A, a high quality machine, dating from the 1930's, which was even used by the BBC as a broadcasting turntable!

Precision Motors and Control Systems for Leadscrew Automation

Depicted here, are two external rotor, polyphase, electronic commutation motors, fitted to custom mounting plates, ready to be installed in disk recording systems, to control the leadscrew.

These are very high precision motors, with features allowing accurate, closed-loop control of speed over a wide range, as well as positioning applications. A combination of hall sensor arrays and high resolution encoders makes them extremely versatile, compatible with a wide range of lathes.

New Styling for Agnew Analog Transformers

Our popular range of premium transformers and iron-core inductors just got prettier!

No need to hide your transformers!

With powder coated end-bells in Agnew-cream-white and our fancy engraved stainless steel product plates riveted on, with type designation and serial number stamped by hand as a seal of approval following our extensive testing and quality control procedures, our transformers now look as good as they are!

Rek-O-Kut Model V: Repair and 50 Hz Conversion

As with the vast majority of disk recording lathes of US manufacture, this 1956 Rek-O-Kut Model V was configured to spin at the correct speeds when powered by 50 Hz mains. One of our customers imported it from the USA and wanted to run it at 230 VAC/50 Hz European mains power. We have encountered this situation countless times by now. We recently also described how we converted a Presto MRC16 to 50 Hz operation by making new rubber rollers to different dimensions, while some years back, we developed the first version of Type 191, a stable electronic frequency converter for professional disk mastering lathes, which are often impractical or costly to convert by other means (Lyrec direct-drive motor on Neumann lathes, belt driven Scully lathes, gear-driven Fairchild systems, etc).

New Agnew Analog Product Plates

We are very excited to present our new product plates, featuring our new logo, engraved on stainless steel plates!

The choice of stainless steel as a material for the plates acts as a further statement of our commitment to exceptional quality, to accompany our products throughout their extremely long service life with no deterioration.

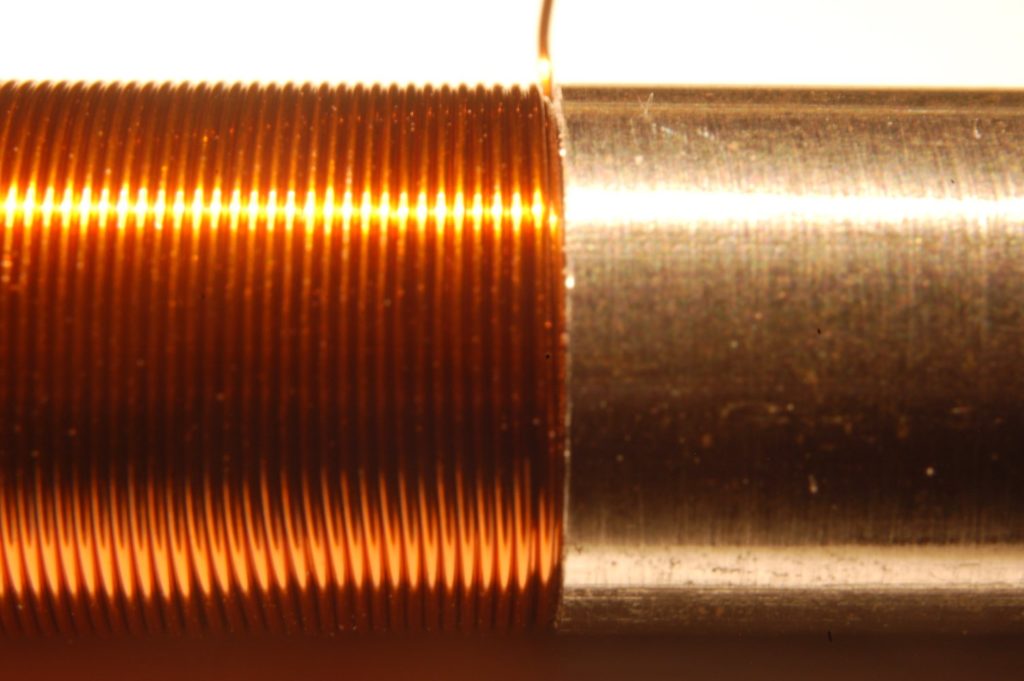

Precision Transducer Development

This item is the latest addition to our collection of experimental transducer prototypes. What you see is a multi-layer miniature winding on a custom machined former, entirely made in-house at the Agnew Analog Research & Development Laboratory.

Restoring Vintage SME Tonearms

Over the past few years, we have restored a number of SME 3009 and 3012 tonearms, covering most of their variants made over the impressively long production life span of this model range.

This outstanding tonearm was first introduced in 1959, setting a standard for high performance tonearm design which is still hard to beat, 60 years later.

We have used our restored SME tonearms on a large number of reference reproduction systems, for our own use and for our customers, such as the Thorens TD160 project which was presented here last February. These systems are excellent for Quality Control in vinyl record manufacturing, to ensure that any defects are caught early.

They are of course also capable of offering an intensely enjoyable, accurate listening experience, coupled with an accurate cartridge.

A New Suspension System for Vintage Lathes

Following up on the progress of the restoration work on a vintage Presto disk recording lathe and the Agnew Analog Reference Instruments Type 6021 Toolpost with integrated oil dashpot, as described in our previous episode, we are now presenting the complete suspension assembly.